Abstract

The large surplus of glycerol derived from the expanding biofuel industry raises economic and environmental concerns regarding disposal. In vitro synthetic biology is emerging as a useful biomanufacturing platform while the conversion of glycerol is rarely investigated. Here we develop a thermostable in vitro synthetic biosystem consisting of three enzymatic cascades for the biotransformation of glycerol into valuable chemicals with different degrees of reduction. Condensation of glycerol, phenol, and ammonium into l-tyrosine is achieved using four enzymes without the assistance of NAD+/NADH-related redox reactions. Production of chemicals with high degrees of reduction (e.g., optically pure l-lactate and d-lactate) is also verified through coupling with an NADH-regeneration system. The biotransformation of glycerol and ammonium into l-serine is achieved using four enzymes with self-sufficient NADH recycling.

Similar content being viewed by others

Introduction

Amidst the increasing environmental concern and the declining availability of petroleum resources, the manufacturing of biofuels (including biodiesel and bioethanol) from sustainable biomass feedstocks has been increasing continuously throughout the world1,2. Glycerol is generated as an unavoidable byproduct during the manufacturing of both biodiesel and bioethanol3. During the transesterification process used in biodiesel production, 1 ton of glycerol is formed for every 9 tons of biodiesel produced4. The global annual production of glycerol is estimated to reach 4.2 million tons in 20205, while the demand for glycerol is predicted to be less than 3.5 million tons. In this context, the large surplus accumulation of glycerol has been a major burden to the biofuel industry and may hamper the widespread adoption of biofuels in the marketplace6. Thus, it is of great importance to explore novel approaches for the biotransformation of glycerol into value-added compounds, both for the development of the biodiesel industry and from the perspective of environmental protection.

In vitro synthetic biology, which involves the artificial design of metabolic pathways and assembly of catalytic elements, is emerging as a promising biomanufacturing platform7,8,9. Compared to the cell-based counterparts, in vitro synthetic systems are superior in many aspects, including: fast reaction rates resulting from the absence of transmembrane transport of substances10, high product yields and easy purification of the target products resulting from the simplified metabolic processes involved11, easy manipulation due to high tolerance to toxic chemicals and temperature fluctuations12, shifting of unfavorable reaction equilibria13, and the diversified design of metabolic pathways14,15. Previously, a variety of in vitro synthetic systems have been explored for the production of valuable chemicals based on renewable biomaterials such as glucose, xylose, sucrose, and glucan11,12,14,15,16,17,18,19. Among these systems, the production of biohydrogen through in vitro metabolic engineering has been studied extensively11,14,18.

Previously, we designed an enzymatic cascade for the conversion of glycerol into pyruvate using three enzymes: alditol oxidase from Streptomyces coelicolor A3 (ALDO), dihydroxy acid dehydratase from Sulfolobus solfataricus (DHAD), and catalase from Aspergillus niger20. This process eliminates the complicated phosphorylation processes typically involved, but unfortunately lacks the ability to supply the reducing power required for the production of chemicals with higher degrees of reduction.

Here, to unlock the potential held in the accumulated surplus of glycerol, the biotransformation of glycerol into value-added chemicals with different reduction degrees is investigated in detail. Through the rational assembly of thermostable enzymes from various species, we construct a completely artificially designed in vitro biosystem for the production of valuable chemicals from glycerol.

Results

Production of l-tyrosine without demand for reducing power

Glycerol was first used to produce l-tyrosine, a chemical typically produced from pyruvate, without a demand for reducing power (Fig. 1). Since tyrosine phenol-lyase has previously been used to catalyze the condensation of phenol, pyruvate, and ammonium into l-tyrosine21, the production of l-tyrosine from glycerol, phenol, and ammonium might be achieved through the coupling of the pyruvate production cascade with tyrosine phenol-lyase. Because higher reaction temperatures are beneficial for the mixing of substances, increasing the reaction rate, lowering the viscosity of the reaction mixture, and reducing the chances of bacterial contamination12,20, thermostable enzymes were selected to verify the feasibility of the artificially designed enzymatic cascade. Tyrosine phenol-lyase from Symbiobacterium thermophilum (StTYRPL, Protein ID: WP_043714225.1) has previously been purified, characterized, and identified as being stable at high temperatures and over a broad range of pH values21,22. Thus, StTYRPL was overexpressed in recombinant form and purified to homogeneity (Supplementary Table 1 and Supplementary Fig. 1).

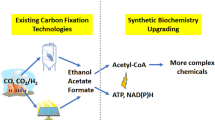

Scheme of in vitro metabolic engineering of glycerol biotransformation. The colored lines and structures indicate the artificially designed pathways for production of l-tyrosine (green), l-lactate (blue), d-lactate (dark yellow), and l-serine (purple). ALDO alditol oxidase from S. coelicolor A3, DHAD dihydroxy acid dehydrogenase from S. solfataricus, OpFDH formate dehydrogenase from O. parapolymorpha DL-1, StTYRPL tyrosine phenol-lyase from S. thermophilum, TtLLDH l-lactate dehydrogenase from T. thermophilus HB8, TiDLDH d-lactate dehydrogenase from T. indicus, PfuGRHPR glyoxylate/hydroxypyruvate reductase from P. furiosus, AfALADH alanine dehydrogenase from A. fulgidus

The production of l-tyrosine was carried out through mixing the four enzymes (ALDO, DHAD, catalase, and StTYRPL) with the substrates (glycerol, phenol, and ammonium). As shown in Fig. 2, 7.71 mM l-tyrosine, with an enantiomeric excess (ee) of greater than 99.9% (Supplementary Fig. 2), was produced from 10.0 mM glycerol in 77.1% yield. The amount of phenol consumed was consistent with the production of l-tyrosine. The production of l-tyrosine was nearly constant throughout the biotransformation process, implying that neither glycerol nor phenol significantly affected the activities or stabilities of the enzymes. No unwanted byproducts, such as acetate, ethanol, and succinate, which often accumulate during cellular metabolic processes, were detected. The l-tyrosine produced was also characterized by LC-MS (Supplementary Fig. 3).

Production of l-tyrosine from glycerol and phenol using enzymatic cascade. Reactions were carried out in 20 mL reaction mixture containing 0.3 U mL−1 ALDO (EC 1.1.3.41, with a specific activity of 0.26 U mg−1), 0.1 U mL−1 DHAD (EC 4.2.1.39, with a specific activity of 0.011 U mg−1), 1000 U mL−1 catalase (EC 1.11.1.6, with a specific activity of 131,600 U mg−1), 12 U mL−1 StTYRPL (EC 4.1.99.2, with a specific activity of 1.96 U mg−1), 0.5 mM pyridoxal 5’-phosphate (PLP), 10 mM glycerol, 25 mM phenol, 150 mM (NH4)2SO4, and 100 mM HEPES-NaOH (pH 7.0) at 50 °C and 300 rpm. Error bars indicate standard errors of three parallel experiments

Production of chemicals with high degrees of reduction

To produce chemicals with higher degrees of reduction from glycerol, the coupling of the NADH recycling system with the enzymatic reactions is technically feasible and easy to implement. Herein, the biotransformation of glycerol into l-lactate and d-lactate was carried out to verify the feasibility of such a system. Formate dehydrogenation was selected as the method of NADH regeneration since it does not introduce unwanted byproducts, thereby simplifying the purification of the target products. As shown in Fig. 1, the pyruvate produced from the oxidation of glycerol was reduced to l-lactate and d-lactate under catalysis by l-lactate dehydrogenase (l-LDH) and d-lactate dehydrogenase (d-LDH), respectively. As a result, one optical lactate molecule was produced from each glycerol molecule, at the cost of one NADH molecule donated from the dehydrogenation of formate.

Previously, d-LDH from Thermodesulfatator indicus (TiDLDH, Protein ID: WP_013906894) was used to produce d-lactate thermophilically; wherein high affinities and rapid conversion rates for both pyruvate and NADH were observed23. Thermus thermophilus HB8 is a hyperthermophilic bacterial strain, and many of its genes have been overexpressed and applied to thermophilic reactions17. Consequently, l-LDH from T. thermophilus HB8 (TtLLDH, Protein ID: YP_144379.1) was selected for l-lactate production. Formate dehydrogenase from Ogataea parapolymorpha DL-1 (OpFDH, Protein ID: EFW95288) has previously been characterized and was shown to possess promising thermostability, a wide pH optimum, and high organic tolerance24. All of these enzymes were overexpressed and purified (Supplementary Fig. 1). The kinetic parameters of these enzymes toward different substrates were determined (Table 1). OpFDH, TtLLDH, and TiDLDH were all thermostable and exhibited 79.0%, 81.1%, and 130.3% of their initial activities, respectively, after incubation at 50 °C for 24 h (Supplementary Fig. 4).

The production of optical l-lactate was carried out by mixing the five enzymes (ALDO, DHAD, catalase, TtLLDH, and OpFDH) with glycerol. NAD+ was added at a concentration of 1 mM. As shown in Fig. 3a, 9.16 mM l-lactate with an ee of 100% (Supplementary Fig. 5) was generated from 10 mM glycerol over 24 h, in 91.6% yield. Formate was consumed alongside the production of l-lactate, and pyruvate was maintained at a concentration of below 0.5 mM throughout the catalytic process. The production of d-lactate was also achieved via replacing the TtLLDH with TiDLDH in the above procedure. As shown in Fig. 3b, 9.73 mM d-lactate with an ee of 100% (Supplementary Fig. 5) was produced from 10 mM glycerol in 97.3% yield over 24 h. Compared to the yield of l-lactate, the higher yield of d-lactate may result from the low Km of TiDLDH toward both pyruvate and NADH (0.05 and 0.03 mM, respectively)23. No unwanted byproducts were detected during the entire biotransformation process for either l-lactate or d-lactate production.

Production of optically pure l-lactate and d-lactate from glycerol using enzymatic cascades. a Production of l-lactate; b Production of d-lactate. Reactions were carried out in 20 mL reaction mixture containing 0.3 U mL−1 ALDO, 0.1 U mL−1 DHAD, 1000 U mL−1 catalase, 3 U mL−1 TtLLDH (EC 1.1.1.27, with a specific activity of 0.54 U mg−1) or TiDLDH (EC 1.1.1.28, with a specific activity of 30.2 U mg−1), 6 U mL−1 OpFDH (EC 1.17.1.9, with a specific activity of 6.11 U mg−1), 10 mM glycerol, 15 mM sodium formate, 1 mM NAD+, and 100 mM HEPES-NaOH (pH 7.0) at 50 °C and 300 rpm. Error bars indicate standard errors of three parallel experiments

Production of l-serine with self-sufficient NADH recycling

To further extend the possible utility of glycerol, we designed a completely artificial pathway for the conversion of glycerol and ammonium into l-serine, with self-sufficient NADH recycling. The synthetic pathway was composed of four enzymes and did not require the addition of costly ATP or ADP (Fig. 1). The glycerate generated from the oxidation of glycerol was converted into 3-hydroxypyruvate under the catalysis of NAD+-dependent glyoxylate/hydroxypyruvate reductase. However, the standard Gibbs free energy (ΔrGθ) of this reaction was estimated to be 20.26 kJ mol−1 (the calculation procedure for ΔrGθ is shown in Supplementary Note 1). In this context, the substrate promiscuity of alanine dehydrogenase was exploited to catalyze the reductive amination of 3-hydroxypyruvate into l-serine (ΔrGθ = −69.64 kJ mol−1). Consequently, ΔrGθ for the production of l-serine from glycerate and ammonium was estimated to be −49.38 kJ mol−1, which ensured that these reactions were thermodynamically feasible. Theoretically, one molecule of l-serine could be produced from one molecule of glycerol and one molecule of ammonium. The glyoxylate/hydroxypyruvate reductase from the hyperthermophilic archaea Pyrococcus furiosus (PfuGRHPR, Protein ID: WP_011011434.1) has been reported to catalyze the reduction of 3-hydroxypyruvate with high catalytic efficiency (kcat/Km)25. The l-alanine dehydrogenase from another hyperthermophilic archaea Archaeoglobus fulgidus (AfALADH, Protein ID: WP_010879161.1) has been shown to be able to catalyze the reductive amination of 3-hydroxypyruvate into l-serine26. Based on these functionalities, PfuGRHPR and AfALADH were overexpressed and characterized (Supplementary Fig. 1).

Since the activity of PfuGRHPR toward the oxidation of glycerate was difficult to assay, its activity toward the reduction of hydroxypyruvate was determined using NADH as the cofactor. As shown in Supplementary Fig. 6, the activity of PfuGRHPR toward hydroxypyruvate reduction decreased sharply in the pH range of 7.0‒9.0, while the reductive amination activity of AfALADH increased in the same range. For the conversion of glycerate into l-serine, the reductive activity of PfuGRHPR should be restricted, while the reductive amination activity of AfALADH should be promoted. In this regard, a pH of 9.0 was chosen for the production of l-serine. The kinetic parameters of the two enzymes toward different substrates were also determined (Table 1). PfuGHPR and AfALADH were both thermostable, exhibiting 110.3% and 64.9% of their initial activities, respectively, after incubation for 24 h at 50 °C and pH 9.0 (Supplementary Fig. 7).

As shown in Fig. 4, 7.13 mM l-serine with an ee of over 99.9% (Supplementary Fig. 8) was produced from 10.0 mM glycerol over 18 h, in 71.3% yield. The concentration of 3-hydroxypyruvate was kept low (below 0.3 mM) during the catalytic process. Glycerate, at a concentration of 2.36 mM, was left as the major byproduct, and no other unwanted byproducts were detected. The fermentative production of l-serine was restricted by the feedback-based inhibition of d-3-phosphoglycerate dehydrogenase by l-serine27,28. The residual glycerate might also be due to similar feedback-based inhibition of the enzymes of the in vitro biosystem by l-serine.

Production of l-serine from glycerol using enzymatic cascade. Reactions were performed in 20 mL reaction mixture containing 0.3 U mL−1 ALDO, 1000 U mL−1 catalase, 7 U mL−1 PfuGRHPR (EC 1.1.1.29, with a specific activity of 2.35 U mg−1), 30 U mL−1 AfALADH (EC 1.4.1.1, with a specific activity of 3.12 U mg−1), 10 mM glycerol, 1 mM NAD+, 150 mM (NH4)2SO4, and 100 mM HEPES-NaOH (pH 9.0) at 50 °C and 300 rpm. Error bars indicate standard errors of three parallel experiments

Discussion

Amidst growing concerns about global energy and anthropogenic climate change, biofuels are believed to be promising alternatives to replace traditional fossil fuels29. Accompanying the rapid expansion of biofuel industry is surplus of glycerol, the main byproduct of biofuel production30. The low price and the large quantity availability of glycerol have made it an ideal feedstock for the production of various chemicals30,31,32. Herein, we have constructed an in vitro biosystem for the biotransformation of glycerol into value-added chemicals with different degrees of reduction.

Glycerol can be converted into pyruvate by an artificial enzymatic reaction cascade composed of ALDO, DHAD, and catalase. Through reactions not involving the participation of NAD+/NADH, pyruvate can be directly used as the substrate for the production of various chemicals such as N-acetylneuraminate, acetoin, and l-tyrosine, the latter of which is illustrated in this study (Figs. 1 and 2). The oxidation of glycerol by O2 does not provide the reducing power required for the production of chemicals with higher degrees of reduction such as lactate, alanine, 2,3-butanediol and ethanol. Thus, coupling the enzymatic pathway with an NADH-regeneration system using formate and formate dehydrogenase was thought to be a potential solution to this problem. The production of both l-lactate and d-lactate in high yields and optical purities verified this assumption (Figs. 1 and 3). During the production of pyruvate from glycerol, glycerate would be produced as an intermediate product. Besides being dehydrated to produce pyruvate, glycerate can also be dehydrogenated to produce 3-hydroxypyruvate and NADH, which might be useful for chemical production processes involving self-sufficient NADH recycling. Herein, the manufacturing of l-serine from glycerol and ammonium is achieved by applying this concept (Figs. 1 and 4).

Both l-tyrosine and l-serine serve as valuable precursors with multiple applications in the food, chemical, pharmaceutical, and cosmetic industries33,34. However, the fermentative syntheses of l-tyrosine and l-serine are restricted by the multistep reactions required and complex regulatory processes. For example, the cellular synthesis of l-serine from glycerol requires at least eight enzymes. Complicated phosphorylation and inhibitory feedback mechanisms are also involved in the metabolic processes (Supplementary Fig. 9). In this study, two artificially designed enzymatic cascades were constructed to manufacture l-tyrosine and l-serine from glycerol, using the minimum number of enzymes. l-Tyrosine, with an ee greater than 99.9%, was produced in 77.1% yield. Further, l-serine, with an ee of greater than 99.9%, was produced from glycerol in 71.3% yield, which is higher than any microbial fermentation processes reported to date35.

Optically pure lactate is a platform chemical that can be utilized in many industrial applications36,37. Nowadays, lactate isomers can be produced with high optical purity through microbial processes. However, a novel technology that can produce lactate from inexpensive raw materials and in high optical purity is still desirable for supporting the potential applications of optically pure lactate. In this study, optically pure l-lactate and d-lactate (ee 100%) were produced from glycerol in high yields. NADH regeneration was achieved through coupling the system with a thermostable formate dehydrogenase, which avoided the production of unwanted byproducts.

The yields and production rates of the systems developed in this study still need to be improved before their industrial applications. When 50 g L−1 glycerol was added in the reaction system for l-lactate production, only 34.4 mM l-lactate was produced in 72 h with a productivity of 0.48 mM h−1 (Supplementary Fig. 10). The low activities of some key enzymes such as ALDO (0.26 U mg−1) and DHAD (0.011 U mg−1) may be the limiting factors requiring future studies. New biocatalysts with high activities, obtained through systematic screening or directed evolution, will be necessary to expand the potential applications of the in vitro synthetic systems. Considering the instability of NAD+ at high temperatures, enzymes that are capable of using thermostable and cheap NAD+ analogs might promote the application of the in vitro biosystem. Systematic optimization of the reaction conditions may also improve the performance of these systems14.

In summary, the large surplus of glycerol derived from the dramatic growth of the biofuel industry has caused economic and environmental concerns regarding its disposal. Using selected thermostable enzymes, we designed a completely artificial in vitro biosystem involving different enzymatic cascades to biotransform glycerol into value-added chemicals with different degrees of reduction. Manufacturing of l-tyrosine was achieved through the condensation of glycerol, ammonium, and phenol without the assistance of NAD+/NADH-related redox reactions. Optically pure l-lactate and d-lactate were produced through coupling with an NADH regeneration system. Production of l-serine from glycerol and ammonium was achieved using a four-enzyme cascade. The in vitro enzymatic system may be a versatile and useful platform for the production of value-added chemicals from glycerol.

Methods

Reagents

Authentic d,l-lactate, d-lactate, l-lactate, d-tyrosine, l-tyrosine, d-serine, l-serine, 3-hydroxypyruvate, and d,l-glycerate were purchased from Sigma-Aldrich (St. Louis, MO, USA). Restriction endonuclease and T4 DNA ligase were purchased from Thermo Scientific (Lithuania). FastPfu DNA polymerase was purchased from TransGen Biotech Ltd. (Beijing, China). The oligonucleotides were synthesized by Sangon Biotech Ltd. (Shanghai, China). The genomic DNA of T. thermophilus HB8 (DSM 579) was purchased from Leibniz-Institut DSMZ (Braunschweig, Germany). All the other chemicals were of analytical pure grade and commercially available.

Construction of recombinant strains

The strains, plasmids, and primers used in this study are listed in the Supplementary Table 1. Escherichia coli DH5α was used for plasmid construction and E. coli BL21(DE3) was used for overexpression of these recombinant proteins. Codon optimized encoding genes of OpFDH, StTYRPL, PfuGRHPR, and AfALADH (the optimized nucleic acid sequences for expression in E. coli can be found in the Supplementary Data 1) were synthesized by General Biosystems, Inc. (Chuzhou, China) and inserted into plasmid pETDuet-1. The resulting recombinant plasmids were then transferred into E. coli BL21(DE3) to construct E. coli BL21(DE3)/pETDuet-OpFDH, E. coli BL21(DE3)/pETDuet-StTYRPL, E. coli BL21(DE3)/pETDuet-PfuGRHPR, and E. coli BL21(DE3)/pETDuet-AfALADH (Supplementary Table 1) for enzyme overexpression. Nucleotide sequence encoding gene of TtLLDH was amplified from the genomic DNA of T. thermophilus HB8 with the primers TtLLDH.f/TtLLDH.r (Supplementary Table 1) and then ligated into restriction sites of BamHI/HindIII of plasmid pETDuet-1. The recombinant plasmid pETDuet-TtLLDH was transferred into E. coli BL21(DE3) to construct E. coli BL21(DE3)/pETDuet-TtLLDH for TtLLDH overexpression.

All the E. coli strains were cultivated in LB medium at 37 °C and 180 rpm. If necessary, ampicillin was added into the medium at a final concentration of 100 μg mL−1.

Preparation of enzymes

Catalase from A. niger was purchased from Sigma-Aldrich (St. Louis, MO, USA). To prepare ALDO, DHAD, TiDLDH, OpFDH, TtLLDH, StTYRPL, PfuGRHPR, and AfALADH, the recombinant strains were cultivated at 37 °C to early logarithmic phase (OD600nm = 0.6‒0.8). Then, IPTG at a final concentration of 1 mM was added into the culture medium. The culture was cultivated for another 12 h at 20 °C for protein overexpression. Cells were harvested and washed twice with 67.7 mM phosphate solution buffer (PBS, pH 7.40).

The recombinant strains were resuspended in binding buffer (20 mM phosphate buffer, 500 mM NaCl, and 20 mM imidazole, pH 7.40) supplemented with 1.0 mM phenylmethylsulfonyl fluoride (PMSF) to prevent proteolysis. Cells were lysed using a continuous high pressure cell disrupter working at 4 °C and 1200 bar. The cell lysate was incubated at 50 °C for 45 min before being centrifuged at 12,000 rpm for 1 h to remove the protein precipitation, cell debris, and intact cells. The supernatant was filtered using a 0.22 μm poly(ether sulfone) (PES) filter, and then loaded onto a 5 mL HisTrap HP column (GE Healthcare, Sweden). Target proteins were eluted with a gradient ratio of elution buffer (20 mM phosphate buffer, 500 mM NaCl, and 500 mM imidazole, pH 7.40), concentrated by ultrafiltration, desalted using a 5 mL HisTrap desalting column (GE Healthcare, Sweden), frozen in liquid nitrogen, and preserved at ‒80 °C until use. The purified proteins were subjected to SDS-PAGE, and the results are shown in Supplementary Fig. 1.

Determination of enzymatic characteristics

The activities of OpFDH, TtLLDH, TiDLDH, PfuGRHPR, and AfALADH were analyzed photometrically by monitoring the absorption of NADH at 340 nm using a UV–visible spectrophotometer (Ultrospec 2100 pro; Amersham Biosciences) with a thermostat water bath. All the reactions were buffered with HEPES-NaOH (100 mM, pH 7.0) and carried out in a 1 mL quartz cuvette at 50 °C. To determine the kinetic parameters of OpFDH, either 0‒40 mM sodium formate (with 1 mM NAD+) or 0‒5 mM NAD+ (with 20 mM sodium fromate) was added. Reactions were started with the addition of appropriate amount of OpFDH. Michaelis-Menten equation was used for calculation of Km and kcat. Similarly, the kinetic parameters of TtLLDH were estimated with the addition of either 0‒100 mM sodium pyruvate (with 0.2 mM NADH) or 0‒1 mM NADH (with 20 mM sodium pyruvate). To determine the enzymatic activity of PfuGRHPR and AfALADH, 3-hydroxypyruvate was used as the substrate. The kinetic parameters of PfuGRHPR toward NADH were determined through the addition of 0‒0.2 mM NADH (with 5 mM 3-hydroxypyruvate). The kinetic parameters of AfALADH toward NADH and 3-hydroxypyruvate were estimated through the addition of either 0‒0.2 mM NADH (with 10 mM 3-hydroxypyruvate) or 0‒10 mM 3-hydroxypyruvate (with 0.2 mM NADH). (NH4)2SO4 at a final concentration of 150 mM was added into the buffer, and the pH was set at 9.0. Three independent experiments were performed for determining the kinetic parameters.

The thermostabilities of OpFDH, TtLLDH, TiDLDH, PfuGRHPR, and AfALADH were characterized through monitoring the remaining enzyme activities after incubation at 50 °C for indicated time intervals.

Cascade reactions

In a previous study, the biotransformation of glycerol into pyruvate was achieved using 0.3 U mL−1 ALDO, 0.1 U mL−1 DHAD, 1000 U mL−1 catalase from A. niger20. The content and ratio of ALDO and DHAD was verified to efficiently convert glycerol into pyruvate. Excess catalase was added to eliminate the H2O2 generated from glycerol oxidation. StTYRPL, OpFDH, TtLLDH, TiDLDH, PfuGRHPR, and AfALADH have higher specific activities than the restricting enzymes ALDO and DHAD. In this study, these enzymes were also added with excess concentrations like the catalase. The l-tyrosine production was carried out in 20 mL reaction mixture containing 0.3 U mL−1 ALDO, 0.1 U mL−1 DHAD, 1000 U mL−1 catalase from A. niger, 12 U mL−1 StTYRPL, 0.5 mM pyridoxal 5’-phosphate (PLP), 10 mM glycerol, 25 mM phenol, 150 mM (NH4)2SO4, and 100 mM HEPES-NaOH (pH 7.0).

To produce optically pure l-lactate and d-lactate from glycerol and formate, reactions were carried out in 20 mL reaction mixture containing 0.3 U mL−1 ALDO, 0.1 U mL−1 DHAD, 1000 U mL−1 catalase from A. niger, 3 U mL−1 TtLLDH or TiDLDH, 6 U mL−1 OpFDH, 10 mM glycerol, 15 mM sodium formate, 1 mM NAD+, and 100 mM HEPES-NaOH (pH 7.0).

Biotransformation of glycerol and ammonia into l-serine was performed in 20 mL reaction mixture containing 0.3 U mL−1 ALDO, 1000 U mL−1 catalase, 7 U mL−1 PfuGRHPR, 30 U mL−1 AfALADH, 10 mM glycerol, 1 mM NAD+, 150 mM (NH4)2SO4, and 100 mM HEPES-NaOH (pH 9.0).

All these reactions were performed in 50 mL conical flasks which were incubated in a thermostatic waterbath shaking at 150 rpm and 50 °C. Three parallel experiments were carried out for each enzymatic cascade reaction. Samples (0.2 mL) were withdrawn at the indicated times before being heat treated for analysis on HPLC. For l-tyrosine production, samples were mixed with 1 N H2SO4 (1:1, v/v) to stop the reaction and dissolve l-tyrosine.

Analytical methods

The protein concentration was determined using the Bradford protein assay (Bio-Rad). The concentrations of glycerol, glyceraldehyde, glycerate, pyruvate, lactate, formate, and 3-hydroxypyruvate were analyzed using an HPLC system (Agilent 1100 series, Hewlett-Packard, USA) equipped with an anion exchange column (Aminex HPX-87H, 300 × 7.8 mm; Bio-Rad, USA) and a refractive index detector, as described by Li et al.38. The analysis was carried out at 55 °C using 10 mM H2SO4 as the mobile phase. The flow rate was 0.4 mL min−1. Stereoselective assays of lactate and tyrosine were performed using an HPLC system equipped with a chiral column (CRS10W, 4.6 mm × 50 mm) and a UV–Vis detector working at 254 nm. The elution was performed at 25 °C using 2 mM CuSO4 as the mobile phase. The flow rate was 0.5 mL min−1. Similarly, stereoselective assays of serine were carried out using 0.1 mM CuSO4 as the mobile phase.

The concentration of tyrosine and phenol was analyzed using an HPLC system equipped with a UV–Vis detector working at 280 nm. The separation was achieved with a reverse phase C18 column (Agilent Eclipse XDB-C18, 4.6 mm × 150 mm, 5 μm) at 40 °C. The elution was carried out using a co-solvent consisting of 100 mM KH2PO4 (pH 2.10) (A) and acetonitrile (B) at a volume ratio of 3:1 and a flow rate of 1 mL min−1.

Serine concentration was quantified using an HPLC system equipped with a UV–Vis detector set at 360 nm. To avoid the influence of ammonium ion on the derivatization of serine, the samples was diluted to suitable multiples. One milliliter of diluted sample was mixed with 0.5 mL NaHCO3 (0.5 M) and 0.5 mL 2,4-dinitrofluorobenzene (DNFB)-acetonitrile (1 mL DNFB in 100 mL acetonitrile), incubated at 60 °C for 1 h, cooled to room temperature, mixed with 8 mL KH2PO4 (20 mM, pH 7.0), and then centrifuged at 10,000 rpm for 10 min. The supernatant was filtered through a 0.22 μm membrane before being injected into the HPLC system. The separation was achieved using a C18 column at 40 °C with 50 mM sodium acetate (A) and water/acetonitrile (volume ratio of 1:1) (B) as the mobile phase (70% A) at a flow rate of 1 mL min−1.

The combination of high-performance liquid chromatography and mass spectrometry was performed to identify the end-product of l-tyrosine production cascade.

Data availability

The authors declare that all the other data supporting the findings of this study are available within the article and its Supplementary Information files and from the corresponding authors upon request.

References

Hill, J., Nelson, E., Tilman, D., Polasky, S. & Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl Acad. Sci. USA 103, 11206–11210 (2006).

Wan Mahmood, W. M. A., Theodoropoulos, C. & Gonzalez-Miquel, M. Enhanced microalgal lipid extraction using bio-based solvents for sustainable biofuel production. Green Chem. 19, 5723–5733 (2017).

Yazdani, S. S. & Gonzalez, R. Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr. Opin. Biotechnol. 18, 213–219 (2007).

Pagliaro, M., Ciriminna, R., Kimura, H., Rossi, M. & Della Pina, C. From glycerol to value-added products. Angew. Chem. Int. Ed. 46, 4434–4440 (2007).

Viana, Q. M., Viana, M. B., Vasconcelos, E. A., Santaella, S. T. & Leitão, R. C. Fermentative H2 production from residual glycerol: a review. Biotechnol. Lett. 36, 1381–1390 (2014).

Lu, X., Vora, H. & Khosla, C. Overproduction of free fatty acids in E. coli: implications for biodiesel production. Metab. Eng. 10, 333–339 (2008).

Zhang, Y. H. P., Myung, S., You, C., Zhu, Z. & Rollin, J. A. Toward low-cost biomanufacturing through in vitro synthetic biology: bottom-up design. J. Mater. Chem. 21, 18877–18886 (2011).

You, C. & Zhang, Y.-H. P. Cell-free biosystems for biomanufacturing in Future Trends in Biotechnology (ed. Zhong, J.-J.) 89–119 (Springer, Berlin, Heidelberg, 2012).

Rollin, J. A., Tam, T. K. & Zhang, Y. H. P. New biotechnology paradigm: cell-free biosystems for biomanufacturing. Green Chem. 15, 1708–1719 (2013).

Li, Z. et al. Enzymatic cascades for efficient biotransformation of racemic lactate derived from corn steep water. ACS Sustain. Chem. Eng. 5, 3456–3464 (2017).

Ye, X. et al. Spontaneous high-yield production of hydrogen from cellulosic materials and water catalyzed by enzyme cocktails. ChemSusChem 2, 149–152 (2009).

Guterl, J. K. et al. Cell-free metabolic engineering: production of chemicals by minimized reaction cascades. ChemSusChem 5, 2165–2172 (2012).

Moradian, A. & Benner, S. A. A biomimetic biotechnological process for converting starch to fructose: thermodynamic and evolutionary considerations in applied enzymology. J. Am. Chem. Soc. 114, 6980–6987 (1992).

Rollin, J. A. et al. High-yield hydrogen production from biomass by in vitro metabolic engineering: mixed sugars coutilization and kinetic modeling. Proc. Natl Acad. Sci. USA 112, 4964–4969 (2015).

Schmidt, S. et al. An enzyme cascade synthesis of ε-caprolactone and its oligomers. Angew. Chem. Int. Ed. 54, 2784–2787 (2015).

Zhang, Y.-H. P. Simpler is better: High-yield and potential low-cost biofuels production through cell-free synthetic pathway biotransformation (SyPaB). ACS Catal. 1, 998–1009 (2011).

Krutsakorn, B. et al. In vitro production of n-butanol from glucose. Metab. Eng. 20, 84–91 (2013).

Martín del Campo, J. S. et al. High-yield production of dihydrogen from xylose by using a synthetic enzyme cascade in a cell-free system. Angew. Chem. Int. Ed. 52, 4587–4590 (2013).

Qi, P., You, C. & Zhang, Y.-H. One-pot enzymatic conversion of sucrose to synthetic amylose by using enzyme cascades. ACS Catal. 4, 1311–1317 (2014).

Gao, C. et al. An artificial enzymatic reaction cascade for a cell-free bio-system based on glycerol. Green Chem. 17, 804–807 (2015).

Kim, D. Y. et al. Development of bioreactor system for I-tyrosine synthesis using thermostable tyrosine phenol-lyase. J. Microbiol. Biotechnol. 17, 116–122 (2007).

Lee, S. G., Hong, S. P., Choi, Y. H., Chung, Y. J. & Sung, M. H. Thermostable tyrosine phenol-lyase of Symbiobacterium sp. SC-1: gene cloning, sequence determination, and overproduction in Escherichia coli. Protein Expres. Purif. 11, 263–270 (1997).

Li, C., Tao, F. & Xu, P. Carbon flux trapping: highly efficient production of polymer-grade D-lactic acid. ChemBioChem 17, 1491–1494 (2016).

Yu, S. et al. Promising properties of a formate dehydrogenase from a methanol-assimilating yeast Ogataea parapolymorpha DL-1 in His-tagged form. Appl. Microbiol. Biotechnol. 98, 1621–1630 (2014).

Lassalle, L. et al. New insights into the mechanism of substrates trafficking in glyoxylate/hydroxypyruvate reductases. Sci. Rep. 6, 20629 (2016).

Schröder, I., Vadas, A., Johnson, E., Lim, S. & Monbouquette, H. G. A novel archaeal alanine dehydrogenase homologous to ornithine cyclodeaminase and μ-crystallin. J. Bacteriol. 186, 7680–7689 (2004).

Li, Y. et al. Construction of Escherichia coli strains producing l-serine from glucose. Biotechnol. Lett. 34, 1525–1530 (2012).

Mundhada, H., Schneider, K., Christensen, H. B. & Nielsen, A. T. Engineering of high yield production of l-serine in Escherichia coli. Biotechnol. Bioeng. 113, 807–816 (2016).

Singh, A., Olsen, S. I. & Nigam, P. S. A viable technology to generate third-generation biofuel. J. Chem. Technol. Biotechnol. 86, 1349–1353 (2011).

Johnson, D. T. & Taconi, K. A. The glycerin glut: Options for the value-added conversion of crude glycerol resulting from biodiesel production. Environ. Prog. 26, 338–348 (2007).

Tan, H. W., Abdul Aziz, A. R. & Aroua, M. K. Glycerol production and its applications as a raw material: a review. Renew. Sust. Energ. Rev. 27, 118–127 (2013).

Sun, D., Yamada, Y., Sato, S. & Ueda, W. Glycerol as a potential renewable raw material for acrylic acid production. Green Chem. 19, 3186–3213 (2017).

Werpy, T. et al. Results of screening for potential candidates from sugars and synthesis gas. Top Value Added Chemicals From Biomass. 1-67 (Department of Energy Washington DC., 2004); https://doi.org/10.2172/15008859.

Dennig, A., Busto, E., Kroutil, W. & Faber, K. Biocatalytic one-pot synthesis of l-tyrosine derivatives from monosubstituted benzenes, pyruvate, and ammonia. ACS Catal. 5, 7503–7506 (2015).

Zhang, X., Xu, G., Shi, J., Koffas, M. A. G. & Xu, Z. Microbial production of l-serine from renewable feedstocks. Trends Biotechnol. 36, 700–712 (2018).

Dusselier, M., Van Wouwe, P., Dewaele, A., Makshina, E. & Sels, B. F. Lactic acid as a platform chemical in the biobased economy: the role of chemocatalysis. Energ. Environ. Sci. 6, 1415–1442 (2013).

Chen, X.-z et al. Efficient bioconversion of crude glycerol from biodiesel to optically pure D-lactate by metabolically engineered Escherichia coli. Green Chem. 16, 342–350 (2014).

Li, L. et al. Metabolic engineering of Enterobacter cloacae for high-yield production of enantiopure (2R,3R)-2,3-butanediol from lignocellulose-derived sugars. Metab. Eng. 28, 19–27 (2015).

Acknowledgements

This research is supported by the National Natural Science Foundation of China (31470164 and 31670041), the Shandong Provincial Funds for Distinguished Young Scientists (JQ 201806), the Young Scholars Program of Shandong University (2015WLJH25), and the Program for Outstanding PhD Candidate of Shandong University.

Author information

Authors and Affiliations

Contributions

C.G. and Z.L. designed the project. C.M., C.G. and P.X. supervised the project. Z.L. performed the experiments and analyzed the experimental data. J.Y. and J.S. helped the purification of the enzymes. Z.L., C.G., C.M. and P.X. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, Z., Yan, J., Sun, J. et al. Production of value-added chemicals from glycerol using in vitro enzymatic cascades. Commun Chem 1, 71 (2018). https://doi.org/10.1038/s42004-018-0070-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-018-0070-7

This article is cited by

-

Tartrate Dehydrogenase in Bacillus Species: Deciphering Unique Catalytic Diversity Through Kinetic, Structural and Molecular Docking Analysis

The Protein Journal (2024)

-

Engineering of a thermophilic dihydroxy-acid dehydratase toward glycerate dehydration for in vitro biosystems

Applied Microbiology and Biotechnology (2022)

-

Novel hydrogel from functionalized glycerol and microfibrillated cellulose: towards an environmentally-friendly design

Cellulose (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.