Prelude to Foundation

The day a paper is out, the world learn about new results, that contributes (hopefully) to the advancement of knowledge. Sometime it is a big step, usually it is just — in the grand scheme of science— an incremental step. Most of the people have no idea about the scientific process that went behind this particular paper, and how researchers arrived to such conclusions. Most people also assume that such process is somewhat linear. If you are into scientific research, you definitely know that this is not the case. You are aware of the trials and errors. The grant race to raise money. The failure of equipments. The orders you have trouble to pass. The small and big problems you have to solve. The one puzzling experiment that destroys your beautiful theory at the last minute, because data are always king. The many reasons we enjoy what we do. In a nutshell, the origins of what I called the emotional roller-coaster.

Our latest paper was published yesterday in Nature Materials. For the readers, this is a one day old story. For us, this is the final touch to a research effort that kept us busy several years. Today, I will try to give you an idea of how we arrived at these results. A peek behind the curtains of science. I did not keep track of every single day, but remember most of the milestones and setbacks we encountered. If you are doing research, this will be a familiar story. If you are not, well, sit down comfortably (this is a long post, reading time around 20 min), grab a beer, and keep reading to learn about the nitty-gritty details of the scientific progress, how work is done, from the original idea to the publication of a paper.

The foundation

Winter 2009. My first PhD student just defended her PhD. We have been working on the fundamentals of ice templating: what happens when you freeze a colloidal suspension ? The basic idea is deceptively simple. It is as a self-assembly process inspired by a natural occurrence of colloids freezing, the freezing of sea ice. When ice crystals are formed, the various impurities originally present in seawater (salt, biological organisms) are expelled and entrapped within the brine channels between the ice crystals. Using ceramic particles instead of biological impurities, we take advantage of this natural segregation principle, while using ice as a natural and environmentally-friendly templating agent. The ice crystals are then removed, leaving pores in the material. I have been working along these ideas for a couple of years. It’s a fun topic.

Ice crystals growing in a colloidal suspension, observed by X-ray computed tomography. © Sylvain Deville

What are the main parameters we should carefully control to process defect-free materials ? We used commercially available ceramic powder so far. Irregular shapes, and distributed sizes. The main conclusion of her PhD is that this is actually awfully complex. It might be time to move to a simpler, more model system, to better understand and control what happens.

One old and kind of obvious idea came back to my mind: what would happen if we used anisotropic particles, like needles or platelets ? How would they behave in front of the water/ice interface ? Could we possibly align and/or order them, like playing cards organize in your hands ? Could we take advantage of this alignment to get unique properties ? People have been freezing colloidal suspensions for a while, and no one thought about this —or at least tried— , which surprises me. Time to investigate.

First, the money. I apply for a grant at the ANRT, which should found the salary of the PhD student. These grants require a collaboration with an industrial partner, practical applications of the work should not be too far. This seemed to be a perfect topic: they are several properties that could benefit of the alignment of anisotropic particles. Saint-Gobain likes the idea, jumps into the train, and off we go.

This is 20 min from the lab. One of the reason why you should definitely come to work with us. Picture by Salva Barbera, CC-BY2.0 License

Spring 2010. Next step: finding the right candidate. This step is absolutely critical, as, in my (short) experience, any PhD topic become what the student makes of it, depending on what he (she) is good at. Attracting candidates to the lab is the most difficult part of the process for us. We are in the countryside, which is beautiful (Provence !) but far from universities and school. None of us is teaching. There are nevertheless many students coming to the center for their 6 months internship which is part of their master degree. This is how we find most of our candidates. We interview several candidates, until we find this one guy with an interesting background: he is good at both experiments and modeling. Perfect for the topic. He’s happy, we’re happy, everybody’s happy. Let’s get started.

Getting started

Autumn 2010. Florian arrives in the lab, his internship done. First things first: raw materials. Ceramic processing is cooking, we need proper ingredients first. One thing we can intuitively expect: for particles —like other things in life— size matters. Another problem we know from the previous PhD: electrical charge at the surface of our particles also matters. And of course, most platelets particles —such as clay— are highly charged. We need non-charged particles, with controlled particle size. Luckily, we have one perfect candidate: boron nitride (BN). Very low surface charge if any, particle size in the 5-50 microns range, low density.

In the meantime, Florian gets familiar with the state of the art on freezing colloids. First problem we have to fix: we need a stable, well-dispersed suspension. If poorly dispersed, particles are stuck together forming aggregates, like overcooked rice. Such agglomerates will be less likely to reorganize during freezing, and will sediment rapidly, because of their weight. The usual way to disperse and stabilize a suspension is to incorporate polymeric chains that will stick to the surface of particles, preventing them to touching each other. Unfortunately, their adhesion is usually based on surface electrical charges. Non-charged particles are thus more difficult to disperse. After a couple of weeks testing different compounds, we’re getting good results with cellulose. After thorough investigations, we become convinced that cellulose is acting as a dispersing agent for these particles. These results will lead to Florian’s first paper, published in the Journal of the American Ceramic Society. If you are interested in dispersing nitride or carbide powders, you should check it out.

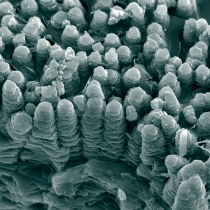

Winter 2010. Time to freeze. Because if you work with me and don’t freeze, you’re fired (unless you give me A LOT of chocolate). Florian is preparing a couple of suspensions with different particle size and particle concentration and freezes them. Let the ice sublimate in the freeze-dryer, before putting them in the furnace and putting everything at high temperature for consolidation. Samples are then cut, before putting them in the scanning electron microscope for observations. The first pictures are promising ! Platelets get aligned! Not everywhere, but it’s promising. Time to investigate the proper conditions to get a good alignment.

Science Needs Plots and Pretty Pics

Florian is a geek. We convince him to build a molecular dynamic model of particles being concentrated by growing crystals, to both understand and optimize the experimental parameters. Because proper science needs colorful plots and pretty pictures, right ? And because it’s currently impossible to look in real-time at particles being moved around by the freezing interface. To confirm the model, we buy some beam-time at the ESRF to scan the frozen structures at high-resolution (50nm), and thus get a 3D representation of the organization of particles.

Molecular dynamics model of the particles being moved around by the freezing interface. Platelets align at the border first. © Florian Bouville

We eventually build a phase diagram helping us to find the optimal parameters to get the maximal packing of particles. These results will later be published in Langmuir, and give us useful guidelines to optimize the processing conditions. We take advantage of these results to look at the properties of the materials we have just created. One of the interest of boron nitride is its good thermal conductivity. This conductivity is anisotropic: it is higher in the plane of the platelets than perpendicular to it. In our frozen materials, this properties is thus directional. This could be used to remove the heat more efficiently in applications where this is needed, such as electronics. I don’t think this is the most promising application, though. We don’t dig further.

Changing the Ingredients

The beautiful nacre of the abalone shell. Also known as the holy grail of materials science. © Sylvain Deville

Spring 2011. Time to move to the good stuff. Back to my first love: the mechanical properties. I still have in mind the amazing structures of the abalone shell that I investigated during my postdoc in Berkeley. In a first approximation, its structure is a brick and mortar arrangement. Due to this amazing structure, its toughness is around 3000 times that of its building blocks.

We previously used freezing to create the bricks , but there’s only so much we can do this way. In particular, we cannot create small (submicronic) bricks. And yet this is the size we need to target if we want to achieve good mechanical properties. The approach is challenging, so other strategies are being explored. But starting with bricks (platelets) of the right dimension would be ideal. We just need to find them. Easier said than done.

The nacre in the abalone is growing layer by layer. We don’t have the time to do that. © Sylvain Deville

Aluminium oxide (alumina) would be a good candidate. A french company was making some a few years ago, we found some pictures in old papers. The company has since been bought, and stopped the production. A colleague of mine in Lyon might have some left in his lab. I give him a call. No luck. Nothing left.

Winter 2011. Andre’s paper is out in Science Magazine. I have known him for a while. We never worked together, but meet each other at conferences. Awesome work as usual. But was catch our attention is the raw materials they are using: alumina platelets, half a micron in thickness, a few microns in diameter. Exactly what we need! He’s emailing me the name of their provider, based in Australia. We eventually managed to order some, and Florian get started as soon as they arrive. Dispersing them is easy. The surface of alumina is usually charged. This is a textbook case. We have a new problem, though. The density of alumina is higher than that of boron nitride, and particles sediment rapidly. We need a fix. In the meantime, Florian keeps working on the molecular dynamics model.

September 2012. I visit an awesome lab in Lyon, invited by Lyderic Bocquet. I give a seminar, spend the day talking with the people in the lab. They’re all physicists, and among other things, I learn about yield-stress fluids, which they create using a polymeric compound commercially available under the trademark name Carbopol. We can use it to create a gel —that will stop the particles from sedimenting— that behave like a fluid as soon as it is put under stress. Exactly what we need. Florian order some, works like magic. Problem solved. Let’s keep moving.

Frozen Lakes

With ice-templating, we are getting porous materials. Our model is nacre, a dense materials. We thus need new tricks to densify our material. Removing the big pores could be easily achieved by pressing, if all the platelets are aligned more or less along the same direction, like playing cards align in your hands when you gently shuffle them. To do this, we need to control the ice crystals orientation, at a large-scale. This is a tough problem. We came up with a solution a few years ago, by combining surface templating and vibrations. But we have never been able to reproduce it. Not robust enough. We need something else.

Digging the literature on ice can be time-consuming. Ice is everywhere, from geophysics to food engineering and materials science. I eventually came across this paper of people looking at ice crystals orientation in frozen lakes. The stream under the frozen surface is inducing a long distance orientation of the ice crystals. Mmmm…. Sounds good, but how can we reproduce this ? Do we really need a lake in the backyard ? It’s not freezing very often in Provence.

I talk with Florian, and we come up with what we now refer to as freezing under flow. We just let the suspension flow across a cold surface, while the temperature is lowered. By doing this, we create a second temperature gradient, and crystals start growing from the sides ! We end up with ice crystals more or less parallel to each other, over several centimeters. The mechanism turns out to be completely different from that occurring in frozen lakes, but hey, we got what we need ! More optimization is required, but we’re on the right tracks.

All the pieces are falling into places. Florian can now press the samples and reach a very high density before the high temperature step. To save time, we do the pressing and high temperature treatment in a single step. The equipment is available in Lyon, and Florian spend a lot of time in the train between Lyon and Avignon. You’d better love traveling if you do research. The microstructures we get are very promising. We achieve a good density, and thanks to the rapid sintering, the platelets keep their original, submicronic size. Time to build upon these structures and increase the complexity of the system.

We’re not the only ones

Winter 2012. Ulrike’s paper is out ! They are freezing platelets ! Exactly the same than ours ! A bad day, Florian is devastated. I pretend to be ok. I have known Ulrike for several years, since she was a visiting scientist at LBNL while I was there as a postdoc, doing the early freezing experiments. She now has a group in the US, and doing work on ice templating. I’m not surprised, thus. Luckily, they just focused on porous materials. So there is plenty of room for us, since we are targeting dense materials. But are they still working on it ? From now on, the clock is ticking.

The Nacre Game

Back to the drawing board. Processing nacre-like materials is a popular game. All the synthetic structures share a common limitation: they are brick and mortar structure, and that’s about it. No other structural arrangement. And yet, having structural features at different length scales is one of the reasons that nacre is so tough. Let’s look at what we can do.

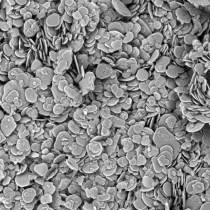

Close-up view of the nacre platelets. Their surface is rough, providing friction when they slide over each other. © Sylvain Deville

The surface of the platelets in nacre is rough. When they are sliding over each other, a lot of friction is generated, dissipating a large amount of energy. The surface of our platelets is smooth. What can we do about it? Thermal or chemical etching ? Not very appealing, we would like to keep the process simple. I suggest adding nanoparticles of the same nature, that hopefully will fuse to the surface during the thermal treatment and create some roughness. They might even join adjacent platelets and create links between them, similar to the inorganic bridges in nacre. Florian enjoys the idea — or it’s just that I am the boss and he diligently obeys— orders some, and is rapidly getting excellent results. Time to put the final touch.

The brick and mortar structure of the abalone shell. The protein layer, between the platelets, can clearly be observed here. © Sylvain Deville

One of the most spectacular feature in nacre is the protein layers present between the platelets. But if we want to use our material at high temperature, which is what ceramics are good for, we do not want any metal or polymer in there. We need something that will melt and fill the remaining gaps, and yet do so after the nanoparticles are fused to the surface. A glassy phase ? That might do the trick. Luckily, we have an expert in the lab. He suggests a mix of calcia and silica, that should melt at high temperature. We have all the ingredients in the lab, already.

A Known Territory

We are now in known territory —ceramic processing— and the tedious work begins. Optimizing the relative proportions of each component to achieve what we need, investigate the high temperature densification of the materials to reach full density. To save time, Florian is investigating the densification mechanism on the still macroporous materials, skipping the pressing step. The mechanical properties of the macroporous materials are in the upper range of what we can expect for cellular materials. The structure can be made similar to that of wood. A fun side work. The results of this will later be published in the Journal of Materials Research.

Spring 2013. Less than a year left for Florian, as his salary is only running for three years, and we’re about to test if the original idea was a good one. Time to measure the mechanical properties of our dense materials. Another tedious step. Making materials. Cutting them into samples. Polishing the sample. Creating the notch for toughness measurement. Breaking the sample. Analyzing the results. And starting all over again with a new composition, changing the amount of nanoparticles and glass phase, to optimize the mechanical properties. We fine-tune the composition, and start getting truly amazing properties. The fracture surface are very tortuous, which is a good sign. Some samples are still holding together as one piece after failure occurs. And this is a purely ceramic materials. Amazing.

Crack path in the synthetic nacre. The crack is deflected at every platelet, dissipating a lot of energy. © Florian Bouville

High toughness, but what about the strength ? Combining high strength and high toughness is one heck of a challenge in materials science. This is the ultimate test. Florian prepares a batch of samples for bending test, and I follow him in the lab to break them. He put the first sample in place and I hold my breath as the load increases. Come on baby, hold it ! Hold hit ! Bang ! The sample just broke. The strength is high. But we need more than one sample of course, as strength value are always somewhat scattered. Second sample goes under the machine. Load increases. Bang ! High strength again. I start to relax. Third sample. High strength again. I think we nailed it. There is remarkably little scattering of the strength value. Florian keeps breaking sample to get a statistically valid strength value. We’re at the usual level of a standard alumina. Terrific.

Our Lottery Ticket

May 2013. Time to wrap up everything in a nice paper with all the cool stuff in it. Florian makes the first draft, and the editing game begins. I usually reach a good manuscript at version 5 or 6, and a final one at version 10 to 15. We send the paper back and forth to each other. Spend a long time on the figures. What’s the best way to explain the process ? How many figure should we shoot for ? Adobe Illustrator is constantly opened on my laptop. The large 27’ screen, hooked up with my laptop, is excellent for this.

I still anxiously check my RSS feed every morning for the newly published paper. Nothing new from Ulrike’s group.

« Morning literature check, no one has reported that they have already finished my still to be completed major projects. Yet. Yay! » @realscientist

One big question left: do we measure the high temperature properties ? This will take a while. Florian’s PhD is almost done, he needs to write his manuscript. We are also scared of being scooped at the last-minute. We eventually decide to go without it, knowing this could be a weakness of our paper.

July 2013. The paper is submitted to Nature… and sent out for review… So far so good, knocking on wood. We hope for the best, knowing there are very, very few materials science papers in Nature.

Not Good Enough

August 2013. Family trip to the US north-west. I have a conference in Portland, and we have been thinking about going back to the US for a while. It’s a good opportunity. Let’s go camping. Lost in the north-west parks and rocky mountains, there is little internet connection, which is good to disconnect. No email for a while, but I am eager to get the reviews back. I never really disconnect in this work. The science is always sitting here, in your mind. Even more so with a big paper submitted.

We stop for an espresso on our way to Portland, and finally get a wifi connection. Reviews are in… and the paper is rejected. “Kidos, why don’t you go play outside for a while?”. One excellent review, one good with a few comments, and reviewer #3 that literally kills us with dubious arguments. Rejected mostly because the results are considered as too specialized for Nature. One thing is clear: not having the high temperature properties definitely killed us.

Working, while waiting in line at Voodoo Doughnuts.

Florian is also in Portland for the conference. We discussed what to do next around a few pints of IPA, based on the reviews. Let’s take advantage of these comments to improve the paper as much as we can. We eventually decide to perform the high temperature measurements: we need rock-solid facts to convince the editors, reviewers, and readers, even if our material is 100% ceramic.

September 2013. Back to the lab after the vacations. We rewrite the paper extensively, using the reviews. Meanwhile, Florian is making more samples and measure their properties at 600°C. Enough to demonstrate these materials can operate at temperatures where ceramic-polymer composites cannot, which was the original idea. We are also improving the measurements of the mechanical properties by using an LVDT sensor, more precise. Florian eventually measures the hardness and stiffness. Triple-check all the calculations again, we don’t want to finish on Retraction Watch because of a typo in an excel spreadsheets. Everything is good. Green lights everywhere. We keep editing the paper over and over, removing all possible traces of hype —scientists hate hype, I’ve learned this the hard way—, fine-tuning the schemes. Weighing each word cautiously. At this point, I stopped numbering the versions a long time ago. Might be worth moving to a proper version control system like GitHub.

Christmas coming earlier

October 29, 2013. I submit the paper to Nature Materials. Should be a good fit for the journal and its readership. The paper is rapidly sent out for review. So far, so good. Again.

Florian, being congratulated by David Clark himself after a brilliant defense.

December 2013. Florian defends his PhD, before leaving to Switzerland (ETH) for a postdoc in Andre’s group. Good for him! It’s a very nice group coming up with a tons of exciting ideas. I’m sure he’ll do great stuff there.

December 18, 2013. Christmas comes earlier this year: the reviews are in, and boy, they’re good ! Even reviewer #3 is happy. We have a few things to fix, but nothing critical. The revised version is submitted after the break, and the paper is accepted on … Valentine’s day. I am apparently not the only one in love with this paper.

February 27, 2014. The proofs of the paper are ready. I immediately spot two big mistakes that appeared during the making of the proofs. Always check the proofs, this is not an optional step. Once printed, it’s too late.

March 23, 2014. The paper is published online. Florian is happy, we’re happy, Pharrell Williams is happy, everybody’s happy. The world discovers our results, CNN is calling us, Wall Street go nuts. Well, not really. But we’re excited to share these results ! The CNRS is happy about these results, issues a press release. This is indeed a cool topic for outreach. The pictures of the abalone shell are stunning if you have never seen them before.

End of the journey ? For us, this still feels just like the beginning. We are already building upon these results, and are working on tons of exciting extensions of this work which I won’t tell you about here, of course… Go figure out yourself, there’s so much we can do with this now. I cannot wait to see what other scientists will come up with.

In Praise of Slow Science

It’s been quite a journey since the original idea. When we publish several papers a year, it’s easy to forget how long it can take to get to something worth publishing. Sometimes it’s fast, usually it’s not. Torn between the deadlines of your grant agencies, the possibilities of being scooped by some group working on the same topic, the finite duration of a PhD, the possibility to increase the number of lines on your CV by slicing your results into less important papers, it’s easy to forget the big picture and publish half-baked papers, that will be less memorable. Reflecting upon this particular journey is a good reminder that good science takes time, and is not a linear, regular process.

Science develops unsteadily, with jerky moves and unpredictable leaps forward—at the same time, however, it creeps about on a very slow time scale, for which there must be room and to which justice must be done. [Slow-Science.org]

Intriguing read. Captures the intricacies and rollercoaster ride of research perfectly.

This is recommended reading for anyone working in academic science. I will definitely pass it on to my colleagues. Kudos on attempting great science and Congratulations on reaching the apex (or should I say plateau before the next uphill climb)

Pingback: Somewhere else, part 123 | Freakonometrics

I don’t know really – it sounds like you’re advocating a very 18th Century ideal of science. Keeping results under your hat and saving them up for yearly meetings, and less regular papers. Is this progress?

In your own history there are a number of milestones that are clearly notable discoveries in their own right. In my view, these would have been worth publishing themselves. So what if they ‘wouldn’t have made Nature’, they are still a valuable contribution to the scientific commons, and perhaps as importantly would have been an opportunity for Florian Bouville to practice writing, and to engage with editors & the mechanics of peer review. As it was, you had him back in the lab when he should have been writing his thesis to feather the nest of your paper’s Nature peer review.

As it is, Florian finishes his PhD without a single paper published, a single citation, or even the inclusion of his surname in your blog post. Is this really a suitable topic for your humble brag of ‘in praise of slow science’?

I replied to your comments on your blog, here -> http://jarvistmoorefrost.wordpress.com/2014/04/04/the-worst-lies-are-the-lies-we-tell-ourselves/#comment-45

Pingback: The worst lies are the lies we tell ourselves | Jarvist Moore Frost

Pingback: Blogroll: Real chemistry : The Sceptical Chymist

Pingback: The top blog posts of 2014 : The Sceptical Chymist